HIDDEN VALLEY – TAILINGS DAM DESIGN

The construction and use of a conventional tailings dam to store tailings from large mining projects has been avoided in Papua New Guinea until Hidden Valley2. At Bougainville, Porgera, Ok Tedi and Tolukuma, all mine tailings after ore processing are discharged to adjacent rivers, causing severe environmental and social impacts matching the scale of each project. The typical case made to justify riverine tailings disposal was the high cost of engineering tailings dams to address risks such as earthquakes and high rainfall rates causing dam failures, as well as sometimes difficult geological conditions and/or rugged topography making suitable sites problematic to find (see Murray et al., 2003, for an honest and critical review).

In the late 1980s, when CRA were actively assessing the potential development of Hidden Valley, riverine tailings disposal or a conventional tailings dam were both considered, while the “… latter was chosen for financial and environmental reasons” (pp 73, Pascoe, 1991). Given that CRA operated Panguna using riverine tailings disposal, largely to avoid the high costs of building and maintaining a conventional tailings dam, this is very curious – and perhaps a subtle recognition by the late 1980’s of the severe impacts from the Panguna mine on Bougainville.

The CRA plan for a tailings dam at Hidden Valley consisted of using a small topographically flat area about 5 kilometres from the deposit (ie. next to the Hamata deposit), using a downstream construction design for the dam wall and discharge of excess waters to the Upper Watut River (Pascoe, 1991). It was expected that this water discharge “…would comply with international standards well before any foreseeable requirements of the closest village” (pp 75, Pascoe, 1991).

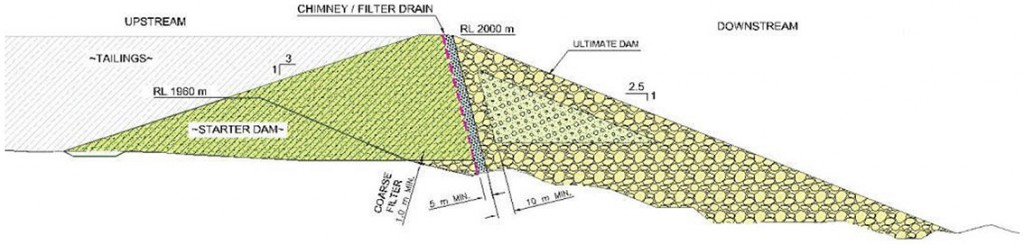

CRA failed to proceed with the project, arguing it was uneconomic at the time, and it was not until the mid-2000s that, after a number of different companies, new owner Abelle Limited, which was 75% owned by Harmony Gold, began steps towards development. Abelle effectively continued the approach by CRA and incorporated a tailings dam in the 2004 Environmental Impact Statement (EIS) (Enesar, 2004; the EIS). The design of the main dam wall is shown in Figure 9. Murray et al. (2010) make the following commentary on the Hidden Valley tailings storage facility: “Building the first on-land tailings containment area sets a precedent for the mining industry in PNG and helps secure a future for the industry by demonstrating the ability to meet modern standards and thereby attract the international investment needed to finance such large ventures” (page 15, Murray et al., 2010).

Thus the Hidden Valley project has proven that it is possible to engineer a modern, acceptable tailings dam in the mountains of Papua New Guinea.

A note of caution, however, is that the existing tailings dam only has a limited capacity for expansion, and it is likely that a second dam will be required in the future if Hidden Valley continues to operate. That is, the original approvals were for a 6.5 year project and 21.5 Mt of tailings compared to the 2013 mineral resources of 117.9 Mt of ore and production by December 2013 of 15.3 Mt of tailings. Presumably a second tailings dam would be part of approvals to operate Hidden Valley beyond the current 6.5 years of mining. The 2004 EIS noted that the Hamata pit could potentially be converted to a second tailings dam after completion of open cut mining.